Maintaining your fleet gets difficult when check engine lights are not quickly reported. As a driver or fleet manager, the sooner you are aware of vehicle malfunctions, the better. Continuing to drive a vehicle with engine problems can lead to more expensive repairs and risky breakdowns.

Diagnostic trouble codes (DTCs) alert us to problems. When a problem is detected, a DTC is generated by the vehicle’s onboarding diagnostic system (OBD). The OBD reports engine malfunction data as DTCs in real time. An alert appears in the form of a check engine or other malfunction-indicating light. You connect an OBD scanner to the OBD port to retrieve the codes. But what if a driver fails to check or act on a code?

With an integrated fleet management system, fleet managers can constantly monitor for issues with remote access to their vehicle’s OBD. Such a reporting system allows you to take immediate action when something goes wrong with your fleet, saving time and lowering repair costs.

DTC Standards

DTCs were developed by the Society of Automotive Engineers to standardize vehicle self-diagnostics and speed up the repair process. Each DTC corresponds to a particular vehicle malfunction.

There are two widely accepted standards for DTCs:

OBD-II Codes

OBD-II codes are in use for light and medium-duty cars. In the US, cars, and trucks built after January 1, 1996 follow the OBD-II code standard.

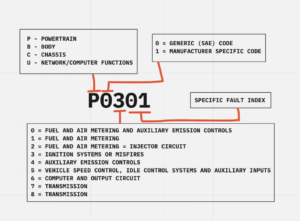

An OBD-II diagnostic trouble code is 5 characters long, containing 1 letter and 4 numbers.

J1939 Codes

J1939 is used for heavy-duty vehicles and heavy equipment. Most vehicles with diesel engines are J1939 compliant. Examples of this type of vehicle would be buses, trucks, or large machines.

How to Read OBD-II DTCs

| Character |

Meaning |

Options |

| Letter |

Indicates the location of the systems fault |

P codes = Powertrain

C codes = Chassis

B codes = Body

U codes = Network and computer functions |

| First Number |

Indicates whether the code is a standard code or manufacturer specific |

0 = Standard Code

1 = Manufacturer-specific component |

| Second Number |

Indicates the subsystem of the fault |

0 = Fuel and air metering and auxiliary emission controls

1 = Fuel and air metering

2 = Fuel and air metering = injector circuit

3 = Ignition systems or misfires

4 = Auxiliary emission controls

5 = Vehicle speed control, idle control systems and auxiliary inputs

6 = Computer and output circuit

7 = Engine Transmission

8 = Engine Transmission |

| Third and Fourth Numbers |

Defines the exact problem |

Range of numbers from 0-9 |

How to Read J1939 DTCs

The scope of the J1939 data protocol is far greater than OBD-II. J1939 actually provides a language for vehicles and heavy-duty machinery to communicate on their CAN bus networks.

A J1939 DTC contains four independent fields which give information about the fault being reported. These fields are:

- Suspect Parameter Number (SPN): Identifies the SPN at fault

- Failure mode identifier (FMI): Identifies the nature of the error

- Occurrence Count (OC): A variable that counts the number of times the error has occurred

- SPN Conversion Method (CM): Defines the byte alignment

DTC Monitoring Improves Fleet Management

DTC codes alert managers of various types of failures in vehicles for prompt solutions and timely repairs. Ideally, your fleet management solution provides a dashboard to view not only DTCs but any variety of vehicle performance data.

Monitor Vehicles From Anywhere

Gone are the days of relying on drivers to report DTCs. With an integrated fleet management system, managers have real-time reporting on their vehicles. Vehicle issues can be addressed immediately, keeping your fleet running as intended.

Heavy-Duty Fleet Telematics

Engine performance can be monitored via loggers connected to the cloud to predict breakdowns based on J1939 data.

Common DTC Codes

Here is a list of the most common DTC codes:

P0606 = a Fault in the Powertrain Control Module (PCM)

P0110 = a Fault in the Intake Air Temperature Sensor Circuit

P0500 = a Vehicle Speed Sensor Problem

P0442 = Evaporative Emission Control System Leak Detected Small Leak

P0700 = Transmission Control System Malfunction

P0456 = EVAP Control System Leak Detected Very Small Leak

P0420 = Catalyst System Efficiency Below Threshold Bank 1

P0171 = System Too Lean Bank 1

P0300 = Cylinder Misfire Detected Random Cylinders

Conclusion

Thanks to onboarding diagnostics and DTCs, vehicle problems can be quickly identified and solved. Yet relying on drivers or manually checking your fleet is unrealistic. For this reason, you want a connected fleet management solution that makes DTC reporting easy. Schedule a demo to see how we can help you better manage your fleet with real-time data monitoring and DTC alerts.

Morey’s vision is to lead the creation of connected products with the ultimate goal of empowering our partners to meet their business needs through smart solutions. Contact us today to discover how partnering with Morey can benefit your company.